Introduction to Thermal Management Materials

As electronic devices continue to proliferate in various sectors, the need for effective thermal management has become increasingly essential. One of the key players in this domain is thermal management materials, which encompass a range of solutions designed to dissipate heat efficiently and maintain operational temperature levels across diverse applications. Understanding these materials, their properties, and their applications can provide significant benefits in designing electronic equipment and ensuring longevity and reliability.

Definition and Importance

Thermal management materials are substances that assist in controlling the temperature of electronic components by conducting, dissipating, or insulating heat. Their importance cannot be overstated; as electronic devices become smaller and more powerful, they generate more heat, which, if not properly managed, can lead to failure or reduced performance. Effective thermal management not only enhances the performance of devices but also increases their lifespan by preventing overheating.

Applications in Electronics

Various sectors rely heavily on thermal management materials to optimize device performance. Common applications include:

- Consumer Electronics: Smartphones, tablets, and laptops that demand compact designs utilize thermal interface materials (TIMs) to maintain temperature.

- Automotive Industry: With the rise of electric vehicles (EVs), thermal management is crucial for battery longevity and performance.

- Telecommunications: Equipment such as servers and routers requires thermal materials to manage heat from continuous operation.

- Aerospace: In high-stakes environments, effective thermal management ensures that electronic components function reliably under varying conditions.

Key Properties that Matter

Choosing the right thermal management material involves scrutiny of various properties, including:

- Thermal Conductivity: The material’s ability to conduct heat is paramount. Higher thermal conductivity ratings typically indicate better performance in heat dissipation.

- Thermal Resistance: The resistance to heat flow should be minimized to ensure efficient thermal management.

- Viscosity: For materials like thermal gels and adhesives, appropriate viscosity enhances application and effectiveness.

- Compliance: The ability of thermal pads to conform to surfaces supports better heat transfer between mating components.

- Durability: Materials should maintain their properties over time, surviving temperature fluctuations and environmental conditions without degradation.

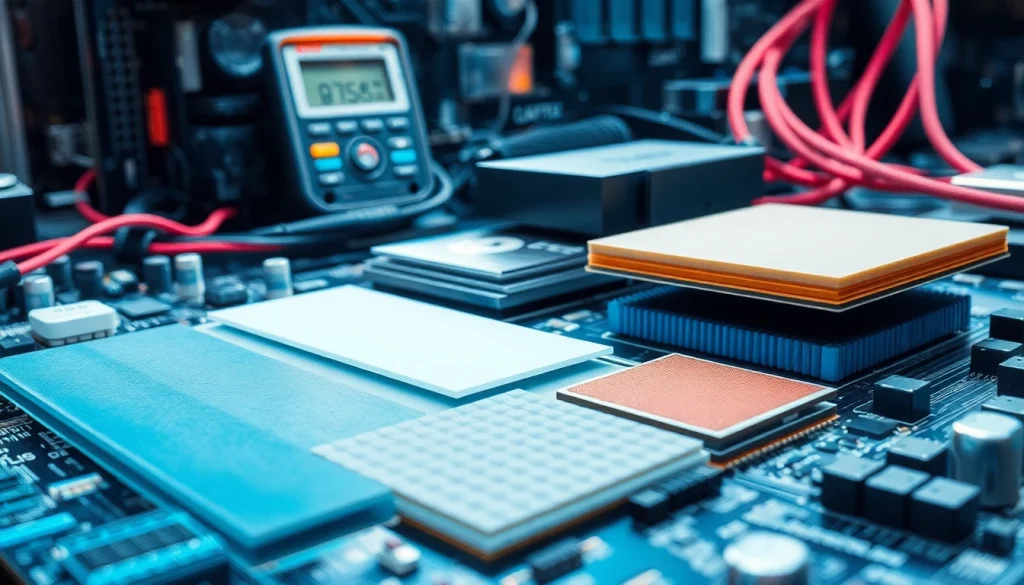

Types of Thermal Management Materials

The market offers a selection of thermal management materials, each suited for specific needs. Understanding their properties and applications can aid in selecting the right material for any project.

Thermal Pads and Their Uses

Thermal pads are widely used in electronics for their excellent thermal conductivity and ease of application. Typically made from silicone, these pads fill gaps between heat sinks and heat-generating electronic components, enhancing heat transfer. Key benefits include:

- Conformability: They easily fit into uneven surfaces.

- High Thermal Conductivity: Advanced pads can reach thermal conductivities exceeding 10 W/mK.

- Ease of Installation: Thermal pads can often be replaced or adjusted with minimal effort.

Gels and Adhesives for Enhanced Performance

Thermal gels and adhesives represent another category of thermal management materials, ideal for scenarios where high thermal conductivity is required in a compact form. They offer several advantages:

- Versatility: They can bond various substrates and fill intricate spaces, enhancing thermal contact.

- Wide Operating Temperature Range: Many thermal gels are designed to function effectively across extensive temperature ranges.

- Long-Term Reliability: They provide durable solutions that can resist moisture and environmental damage, contributing to the longevity of electronic devices.

Comparative Overview of TIMs

Thermal Interface Materials (TIMs) encompass thermal pads, gels, and other types like phase change materials (PCMs). Each type has unique properties.

- Phase Change Materials: These materials undergo a phase change (solid to liquid and vice versa) at certain temperatures, providing effective thermal management by absorbing and releasing heat as they change states. They are highly effective in applications requiring significant heat load management.

- Thermal Adhesives: Ideal for bonding components while also conducting heat, thermal adhesives ensure compatibility across materials, enhancing overall system performance.

- Some Variants: Specific products might blend features (e.g., thermal pads with adhesive backing), making them multi-functional and adaptable to diverse applications.

Performance Metrics and Testing Standards

When evaluating thermal management materials, performance metrics and testing standards help define their effectiveness in various applications. Manufacturers are often subject to stringent compliance standards.

Thermal Conductivity Measurements

Assessing the thermal conductivity of materials is essential. The most common unit for measuring thermal conductivity is W/mK (watts per meter-kelvin). Manufacturers use standardized tests, including:

- ASTM D5470: This standard defines the test method for thermal conductivity of solid materials using the guarded hot plate technique.

- ASTM D3386: Useful for measuring thermal conductivity of materials in service-like conditions, offering insights into real-world performance.

Durability and Reliability Factors

Durability is another crucial aspect of thermal management materials. It encompasses:

- Temperature Cycling: Resistance to thermal shock and extremes that can affect material integrity.

- Moisture Resistance: Many applications subject materials to variable humidity, indicating the need for materials that do not degrade when exposed to moisture.

- Time Degradation: Over time, materials should retain their thermal performance without significant degradation.

Standards Compliance in Thermal Management Solutions

Compliance with international standards ensures that materials meet industry benchmarks for safety, performance, and effectiveness. Manufacturers should ensure their products comply with:

- ISO Standards: These include various regulations tailored to electronic materials specifically regarding environmental and safety protocols.

- RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials, promoting health and safety in electronic devices.

Challenges in Thermal Management

Despite the advancements in thermal management materials, challenges persist that engineers and designers need to address effectively. Understanding these challenges can help in devising appropriate solutions.

Heat Dissipation Issues in Modern Electronics

As electronic devices evolve toward miniaturization, heat dissipation becomes increasingly difficult. Key challenges include:

- Power Density Increases: Higher power densities in circuits lead to increased heat generation that may exceed cooling capabilities.

- Compact Device Designs: Space-constrained designs limit the size and effectiveness of heat sinks and other cooling solutions, necessitating highly effective thermal materials.

Material Selection for Various Applications

Selecting appropriate materials for specific applications can pose challenges, such as balancing cost, performance, and compatibility. Effective strategies include:

- Understanding Application Requirements: Determining the specific thermal, physical, and chemical requirements for the application is essential.

- Benchmark Testing: Conducting performance testing with selected materials can help identify the most appropriate solution for a given application.

Future Trends in Thermal Management Materials

Anticipating future trends is vital for staying ahead in the field of thermal management. Innovations may include:

- Nanotechnology: Incorporating nanomaterials may enhance thermal conductivity and reduce overall material weight.

- Smart Materials: Future thermal materials may include features for real-time monitoring of temperature and performance feedback.

- Recyclable and Sustainable Materials: As sustainability becomes a higher priority, the development of eco-friendly thermal management materials is likely to gain traction.

Conclusion and Future Directions

In summary, an understanding of thermal management materials is essential for optimizing electronic device performance and ensuring longevity. By emphasizing their properties, applications, and challenges, engineers can make informed decisions that drive advances in technology.

Recap of Thermal Management Insights

Thermal management materials play a crucial role in modern electronics by ensuring efficient heat dissipation and maintaining operational temperatures across a variety of applications. Their development is closely linked to technological advancements and consumer demand for smaller, more powerful devices.

Looking Ahead: Innovations in Materials

The field of thermal management is ripe for innovation, with emerging technologies promising enhancements in efficiency, sustainability, and performance. By embracing these changes, engineers and manufacturers can create products that exceed current performance standards.

Final Thoughts on Effective Solutions

Continued research and development in thermal management materials will be pivotal to overcoming current challenges in heat management in electronics, leading to smarter, more efficient, and environmentally friendly solutions.